How Heavy Copper PCB Enhances Power and Reliability in Modern Electronics

2025-08-25

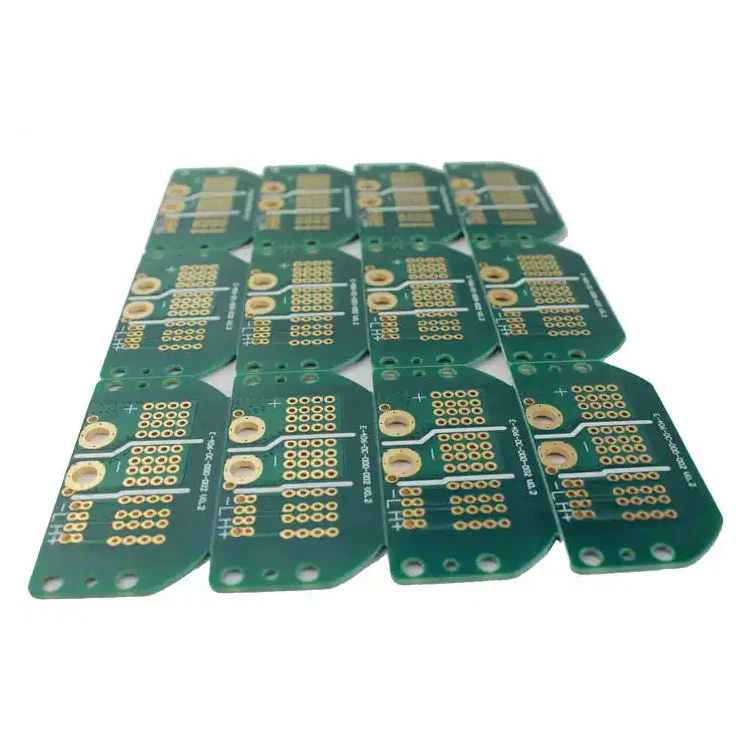

In today’s rapidly evolving electronics industry, where high power density, thermal management, and reliability are critical, Heavy Copper PCBs have become one of the most sought-after solutions. These printed circuit boards are designed with thicker copper layers, typically ranging from 3 oz/ft² to over 20 oz/ft², which is significantly higher than the standard PCB copper thickness of 1 oz/ft².

Heavy Copper PCBs are commonly used in applications where circuits must handle high currents, withstand frequent thermal cycles, and provide mechanical stability under extreme environmental conditions. From automotive power distribution to renewable energy systems, their role in enabling robust electronic designs cannot be overstated.

Key Benefits of Heavy Copper PCBs

-

High Current Carrying Capacity – Thicker copper layers allow for efficient power transfer without overheating or failure.

-

Enhanced Thermal Management – Better heat dissipation prevents hotspots and ensures longer product lifespan.

-

Improved Mechanical Strength – The added copper increases the board’s durability under harsh conditions.

-

Compact, High-Power Designs – Enables smaller PCB sizes while still supporting high-performance requirements.

-

Superior Reliability – Designed for mission-critical industries like aerospace, medical, and automotive electronics.

Heavy Copper PCBs are not just about thickness; they’re about enabling innovation in high-performance electronics. They make it possible to design compact yet powerful devices without compromising safety or efficiency.

How Heavy Copper PCBs Are Manufactured

The manufacturing process of Heavy Copper PCBs is more complex than that of standard PCBs. It involves specialized techniques to handle the increased copper thickness while maintaining precise trace geometries and layer bonding strength.

Key Manufacturing Steps

1. Substrate Preparation

The process starts with selecting a high-quality base material such as FR4, polyimide, or metal-core laminates, depending on the application’s thermal and mechanical requirements.

2. Copper Lamination

Unlike conventional PCBs that use standard copper foils, Heavy Copper PCBs require thicker foils or electroplated copper. The lamination process involves bonding these thicker copper layers securely onto the substrate under controlled pressure and temperature.

3. Etching Process

Etching thick copper layers demands precision. Advanced chemical etching techniques ensure clean, sharp trace edges without undercutting, which is critical for signal integrity and circuit performance.

4. Plating and Via Formation

For multi-layer Heavy Copper PCBs, through-hole plating must be carefully controlled to ensure consistent conductivity between layers, especially when high currents are involved.

5. Surface Finishing

Surface finishes such as ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), or OSP (Organic Solderability Preservative) are applied depending on the product’s soldering requirements and expected shelf life.

6. Testing and Quality Control

Heavy Copper PCBs undergo strict electrical testing, thermal cycling simulations, and mechanical stress tests to ensure they meet international standards like IPC-6012.

Heavy Copper PCB Specifications Table

| Parameter | Specification |

|---|---|

| Copper Thickness | 3 oz/ft² – 20 oz/ft² |

| Minimum Trace Width | 0.25 mm |

| Minimum Spacing | 0.25 mm |

| Layer Count | 1 to 20+ |

| Base Material | FR4, Polyimide, Metal Core |

| Surface Finish Options | ENIG, HASL, OSP, Immersion Tin |

| Operating Temperature | -55°C to +180°C |

| Applications | Automotive, Aerospace, Power Electronics, Renewable Energy |

This detailed production process ensures that Heavy Copper PCBs deliver high durability, excellent thermal performance, and long-term reliability, even in the most demanding environments.

What Makes Heavy Copper PCBs Ideal for High-Power Applications

High Current Handling for Power Electronics

Heavy Copper PCBs are the backbone of modern power electronics. With the increasing demand for electric vehicles, renewable energy converters, and industrial automation, electronic circuits must manage ever-higher currents without failures. Thick copper layers allow these boards to sustain currents exceeding 50A without overheating, making them perfect for high-power applications.

Thermal Management and Reliability

In electronics, heat is the silent killer. Heavy Copper PCBs handle heat more efficiently by providing low thermal resistance and evenly distributing energy across the board. This capability reduces the need for additional heatsinks and enhances overall device reliability.

Compact Design Without Compromising Performance

With the rising demand for miniaturization, engineers are challenged to design compact devices that deliver high power outputs. Heavy Copper PCBs enable manufacturers to reduce board size while maintaining exceptional performance.

Application Industries

-

Automotive Electronics – Power distribution units, EV battery management systems.

-

Industrial Automation – High-current motor controllers, robotics.

-

Renewable Energy – Solar inverters, wind turbine controllers.

-

Aerospace & Defense – High-reliability avionics and radar systems.

-

Medical Devices – Imaging systems and power-driven diagnostic equipment.

FAQs and Choosing the Right Heavy Copper PCB Manufacturer

FAQ 1: What is the difference between Heavy Copper PCBs and standard PCBs?

Answer: Standard PCBs usually have a copper thickness of 1 oz/ft² or less, designed for low-current, low-power applications. In contrast, Heavy Copper PCBs feature copper thicknesses of 3 oz/ft² or higher, enabling them to handle higher currents, provide better heat dissipation, and ensure stronger mechanical integrity. They are ideal for demanding environments and high-power systems.

FAQ 2: How do I choose the right Heavy Copper PCB for my project?

Answer: Choosing the right PCB depends on several factors:

-

Current Requirements – Determine the maximum current your circuits must handle.

-

Thermal Conditions – Evaluate whether your application needs advanced heat management.

-

Layer Count – Multi-layer PCBs may be necessary for compact yet powerful designs.

-

Material Selection – For extreme environments, high-Tg laminates or metal cores may be ideal.

-

Compliance Standards – Ensure the manufacturer meets IPC and RoHS standards for safety and performance.

Why Choose Fanway for Heavy Copper PCBs

When it comes to Heavy Copper PCBs, precision engineering and consistent quality make all the difference. Fanway specializes in delivering high-performance PCBs tailored to your specific power, thermal, and size requirements. With cutting-edge manufacturing capabilities and strict quality controls, we ensure every board meets global reliability standards.

Whether you’re designing next-generation automotive systems, industrial power solutions, or renewable energy platforms, Fanway provides the expertise and production capacity to turn your ideas into reliable, high-quality products.

Contact us today to discuss your Heavy Copper PCB requirements and discover how Fanway can help you achieve the perfect balance of performance, durability, and innovation.