How to Choose the Right Galvanized Steel Coil?

2025-04-09

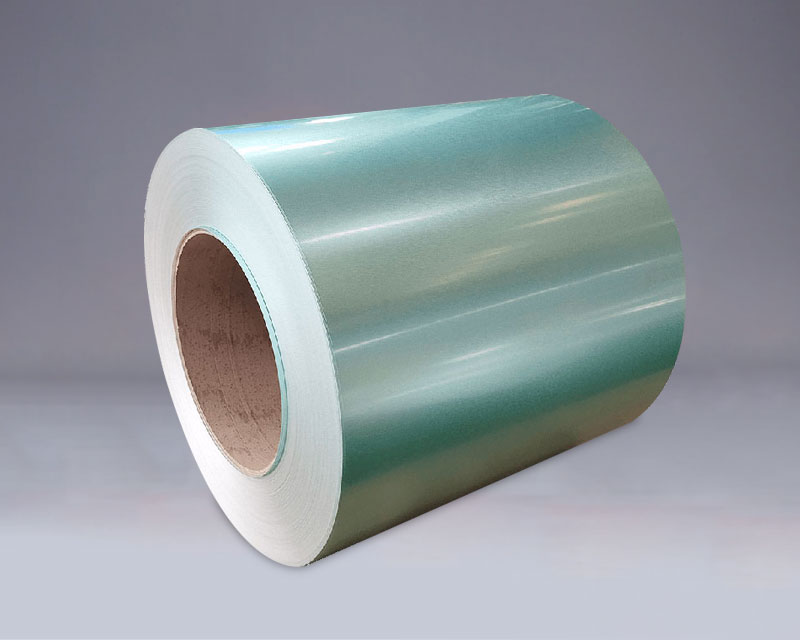

With so many grades, coatings, and finishes available, selecting the right galvanized steel coil can be overwhelming. Whether you're sourcing material for construction, fabrication, or resale, it's important to understand what to look for. This guide will help you make a confident and informed decision.

1. Consider the Zinc Coating Thickness (Zinc Weight)

The thickness of the zinc coating is often denoted as Z100, Z275, etc. (The number refers to the total weight of zinc in grams per square meter.)

- Higher zinc weight = better corrosion protection

- For outdoor applications or marine environments, go for Z275 or higher

- Indoor or less aggressive environments may only need Z100–Z140

2. Know Your Steel Grade

The steel underneath the zinc can vary in hardness, flexibility, and strength. Common grades include:

- DX51D: Standard structural grade for general use

- SGCC: Common in Asian markets, suitable for cold forming

- S350GD: High-strength grade, great for construction

Always check that the grade matches your application — bending, welding, and load-bearing may require specific properties.

3. Surface Finish Matters

- Regular spangle: A classic crystallized finish, often used for aesthetic purposes

- Zero spangle: Smoother and more uniform, often preferred for painting or coating

- Minimized spangle: A middle ground offering good appearance and functionality

4. Coil Width and Thickness

Standard widths range from 600mm to 1500mm, while thickness typically ranges from 0.2mm to 3.0mm. Choose dimensions that fit your processing machines or final product needs.

5. Look for Quality Certifications

Reputable manufacturers will offer:

- ISO 9001 certification

- Mill test reports (MTC)

- Compliance with ASTM, EN, or JIS standards

These indicate consistency, quality, and adherence to global standards.

6. Don’t Ignore Packaging and Shipping

Ask about:

- Rust-proof packaging

- Edge protection

- Wooden pallets or steel skids

This ensures your steel arrives in top condition, ready to use.

Conclusion

Choosing the right galvanized steel coil requires more than just comparing prices. Consider your project’s specific requirements — from corrosion resistance and strength to finish and processing needs. Investing time in selection pays off in long-term performance and fewer headaches down the road.