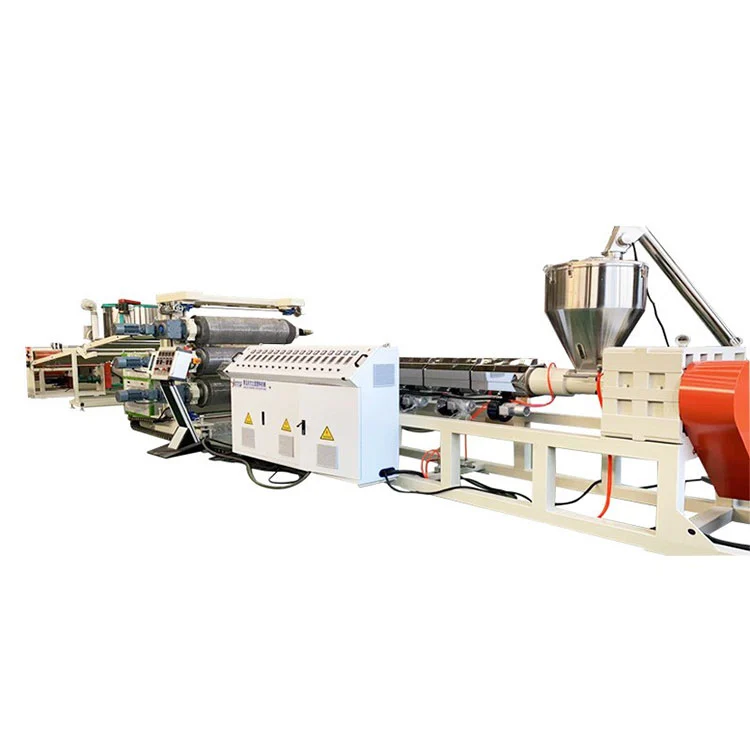

How to Choose the Right Plastic Sheet Extruder Machine for Your Needs

2025-05-16

Investing in a Plastic Sheet Extruder Machine can significantly boost your production capabilities, but selecting the right model is crucial for maximizing performance and ROI. Here’s a practical guide to help you make an informed decision.

1. Know Your Material Requirements

Different extruders are designed for specific materials. Determine which type of plastic you’ll be processing:

PP, PE – Lightweight and widely used

PET – Great for transparent and food-grade applications

PVC – Durable and flexible

ABS or PS – Used in automotive, electronics, and more

Make sure the machine is compatible with your target material.

2. Consider Sheet Specifications

Define your desired sheet width, thickness, and surface finish. A wider die and stronger haul-off system are needed for thicker or wider sheets.

Adjustable die sizes allow flexibility in product specs

Polishing rollers are important for glossy finishes

3. Check Production Capacity

Choose a machine with a throughput rate (kg/hour) that aligns with your production goals. Over- or under-sizing can lead to inefficiencies or wasted resources.

4. Automation and Control System

Modern extruders come with advanced control systems such as:

PLC or HMI interfaces

Automatic thickness control

Real-time monitoring of temperature, pressure, and speed

These features enhance consistency and reduce manual labor.

5. Energy Efficiency

Look for models with energy-saving heaters, efficient motors, and precise temperature control to minimize operating costs over time.

6. After-Sales Support

Reliable technical support, spare parts availability, and training services from the manufacturer are crucial for minimizing downtime and maintaining productivity.

Conclusion

Choosing the right plastic sheet extruder machine depends on your product needs, raw materials, and desired output. By considering capacity, automation, energy use, and vendor support, you can ensure a smooth and profitable production process.