The Basics of Square Nuts: Applications, Advantages, and Varieties

2024-07-24

Square nuts are a common yet often overlooked component in various construction and engineering projects. Their unique shape and functionality make them ideal for specific applications where traditional hex nuts might not be suitable. In this blog, we will explore the basics of square nuts, their applications, advantages, and the different varieties available.

What are Square Nuts?

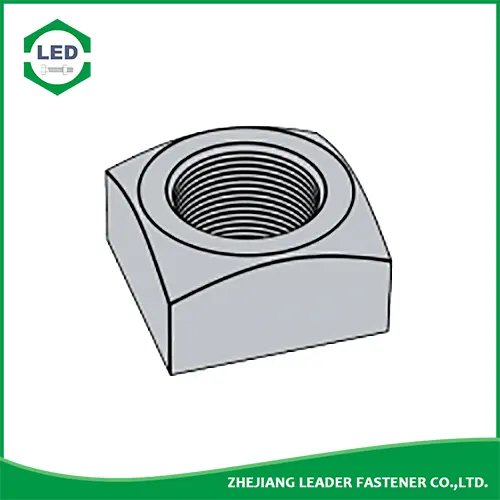

Square nuts, as the name implies, are nuts with a square-shaped body. They are threaded internally and are used in conjunction with bolts to fasten materials together. The four-sided shape provides a larger surface area in contact with the material, offering greater resistance to loosening due to vibration.

Applications of Square Nuts

Square nuts are used in a wide range of applications across different industries. Some common uses include:

1. Woodworking: Square nuts are frequently used in woodworking projects because their shape prevents them from rotating in wood. This makes them easier to tighten without the need for additional tools.

2. Construction: In construction, square nuts are used for structural applications, including framing and securing metal components. Their shape allows for better torque distribution, providing a more secure fit.

3. Automotive: Square nuts are used in vintage and antique vehicles, as they were commonly used in the past. They are often needed for restoration projects to maintain the authenticity of the vehicle.

4. Railways: Square nuts are used in railway applications for securing tracks and other components due to their durability and resistance to loosening from vibrations.

Advantages of Square Nuts

Square nuts offer several advantages over other types of nuts:

1. Increased Surface Area: The square shape provides a larger surface area, which distributes the load more evenly and reduces the risk of damaging the material being fastened.

2. Resistance to Loosening: Square nuts are less likely to loosen under vibration compared to hex nuts, making them ideal for applications where stability is critical.

3. Ease of Use: In woodworking and other applications, square nuts can be easily embedded into materials, preventing them from spinning and making it easier to tighten or loosen the bolt.

4. Enhanced Grip: The four sides of a square nut provide more gripping edges, making it easier to apply torque with a wrench or pliers.

Varieties of Square Nuts

Square nuts come in various materials and finishes to suit different environments and requirements. Some common varieties include:

1. Steel Square Nuts: These are the most common type and are used in general applications. They offer strength and durability.

2. Stainless Steel Square Nuts: These nuts are corrosion-resistant and are used in environments where moisture or chemicals are present.

3. Brass Square Nuts: Brass nuts are used in applications where conductivity and resistance to corrosion are important, such as in electrical work.

4. Zinc-Plated Square Nuts: These nuts are coated with zinc to provide additional corrosion resistance, making them suitable for outdoor applications.

Conclusion

Square nuts are versatile and reliable fasteners that offer unique advantages in various applications. Whether you are working on a woodworking project, constructing a building, or restoring a vintage vehicle, understanding the benefits and varieties of square nuts can help you choose the right fastener for your needs. Their increased surface area, resistance to loosening, ease of use, and enhanced grip make them an excellent choice for many tasks.