The use of high-frequency PCB in vehicle radar systems

2025-06-16

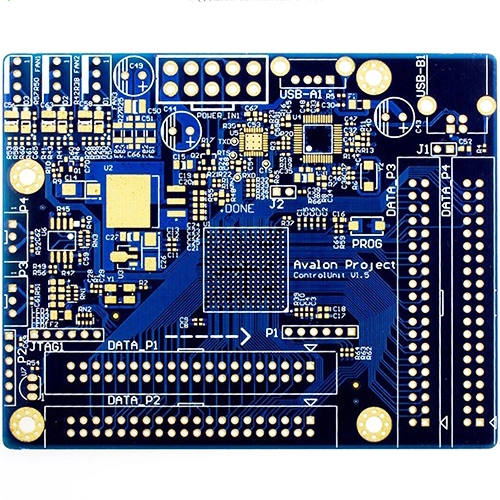

High-frequency PCBs play a critical role in vehicle radar systems, particularly in advanced driver assistance systems (ADAS) and autonomous vehicles. Radar systems require precise, fast, and reliable signal processing, and the performance of the PCB is key to achieving this. Here are some key ways high-frequency PCBs are used in vehicle radar systems:

1. Signal Integrity

Radar systems rely on the transmission and reception of high-frequency electromagnetic waves, often in the GHz range (e.g., 24 GHz, 77 GHz). High-frequency PCBs ensure signal integrity, minimizing loss and distortion. These PCBs typically use materials with low dielectric loss, such as PTFE (Teflon) or other high-performance laminates, to maintain high signal fidelity.

2. Miniaturization

Radar systems in vehicles are designed to be compact to fit in the limited space available. High-frequency PCBs enable the miniaturization of components while maintaining the necessary signal quality. This is achieved through advanced PCB design techniques, like high-density interconnects (HDI) and optimized layer stacks.

3. Thermal Management

Vehicle radar systems often operate in harsh environments with varying temperatures. High-frequency PCBs need to be thermally stable to ensure proper operation across a wide temperature range. Materials used in these PCBs must have good thermal conductivity to dissipate heat generated by high-frequency signals and prevent performance degradation.

4. Reduced Crosstalk

As radar systems involve high-speed signals, minimizing crosstalk (interference between signals) is crucial. High-frequency PCBs are designed with tight trace spacing, controlled impedance, and ground planes to reduce the risk of crosstalk, ensuring accurate signal reception and transmission.

5. Antenna Integration

In many vehicle radar systems, the PCB may also incorporate the radar antenna. High-frequency PCBs enable the integration of antennas into the PCB, reducing the need for additional components and enhancing the system’s overall performance. The design of the PCB helps optimize the antenna’s radiation patterns, which is critical for radar range and accuracy.

6. Low Noise and High Stability

Radar systems require low noise for precise detection and measurement. High-frequency PCBs are designed with low-noise materials and careful routing to ensure high stability, enabling radar systems to reliably detect objects, even at longer ranges or in challenging environmental conditions.

7. Multi-layer PCB Designs

Due to the complexity of radar systems, multiple layers are often required for routing signals, power, and ground. Multi-layer PCBs allow for better separation of high-frequency signals from power and ground planes, which minimizes interference and enhances performance. These designs also support more complex radar system architectures.

8. Reliability and Durability

Radar systems need to perform reliably under varying conditions (e.g., vibration, humidity, extreme temperatures). High-frequency PCBs are designed with ruggedness in mind, using materials and manufacturing processes that ensure long-term durability and stable operation in automotive environments.

In summary, high-frequency PCBs are integral to the performance and reliability of vehicle radar systems. They ensure that radar signals are transmitted and received accurately, supporting advanced functions like collision avoidance, adaptive cruise control, and lane-keeping assistance. Their role is vital in achieving the high-speed, low-latency, and noise-free operation required for these systems to function effectively in real-time traffic scenarios.

As a professional manufacturer and supplier, we provide high-quality products. If you are interested in our products or have any questions, please feel free to contact us.