Why Copper Braid is the Ultimate Solution for Electrical Grounding and Shielding?

2025-08-13

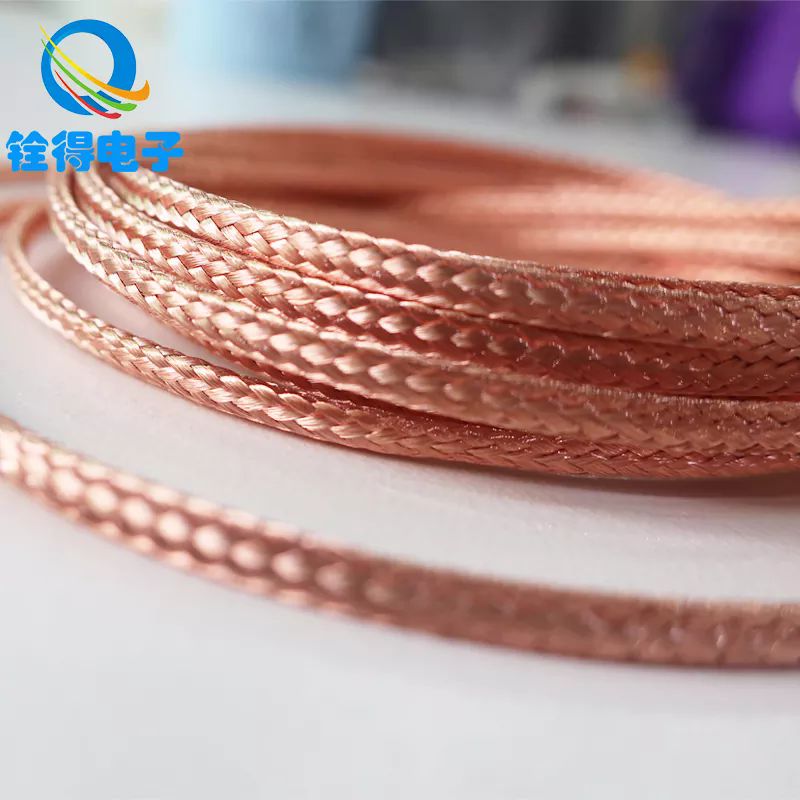

Copper braid is a versatile and highly efficient material used in electrical grounding, shielding, and flexible conductive connections. Its superior conductivity, flexibility, and durability make it a preferred choice across industries like aerospace, telecommunications, and automotive engineering. But why exactly should you consider copper braid for your applications? Let’s dive deep into its benefits, technical specifications, and common use cases.

The Superiority of Copper Braid in Electrical Applications

Copper braid stands out due to its excellent electrical conductivity, corrosion resistance, and mechanical flexibility. Unlike solid copper wires, braided copper can withstand constant movement without breaking, making it ideal for dynamic environments. Here’s a breakdown of its key advantages:

High Conductivity: Copper’s low resistance ensures minimal energy loss.

Flexibility: The braided structure allows bending and twisting without fatigue.

Durability: Resistant to wear, vibration, and extreme temperatures.

EMI/RFI Shielding: Effectively blocks electromagnetic and radio frequency interference.

Industries rely on copper braid for grounding systems, battery connections, and even lightning protection. Its adaptability makes it indispensable in both industrial and consumer electronics.

Detailed Product Specifications (Technical Breakdown)

To ensure you select the right copper braid for your needs, here’s a detailed overview of standard parameters:

| Parameter | Specification |

|---|---|

| Material | Pure copper (optional tinning available) |

| Strand Diameter | 0.05mm – 0.20mm |

| Braid Width | 5mm – 100mm (customizable) |

| Current Carrying Capacity | Up to 500A (varies with cross-section) |

| Temperature Range | -50°C to +150°C |

| Insulation Options | Bare, PVC, or silicone coated |

For specialized applications, custom configurations are available.

Copper Braid Common Questions (FAQ Section)

Q: How do I determine the right width and thickness for my application?

A: The selection depends on current load and flexibility requirements. For high-current applications (e.g., welding cables), thicker braids (20mm+) are recommended. For flexible connections in robotics, narrower braids (5mm–10mm) suffice. Always consult an engineer for precise calculations.

Q: Does tinned copper braid offer significant advantages over bare copper?

A: Yes. Tinning enhances oxidation resistance, making it suitable for humid or corrosive environments (e.g., marine applications). However, bare copper provides marginally better conductivity and is more cost-effective for indoor use.

Why Choose Quande for Your Copper Braid Needs?

At Quande, we specialize in high-performance copper braids tailored to industrial and commercial demands. Our products undergo rigorous testing to ensure compliance with international standards (ISO, UL, RoHS). Whether you need standard sizes or custom-engineered solutions, we deliver reliability and precision.

Contact Us today to discuss your requirements or request a free sample. Our technical team is ready to assist with material selection, prototyping, and bulk orders.

This comprehensive guide ensures you understand copper braid’s critical role in modern electronics while helping you make an informed purchasing decision. For further details, explore our product catalog or reach out for personalized support.