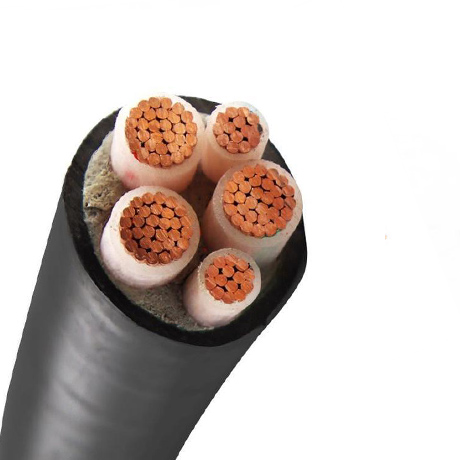

marine shipboard cable

Marine shipboard cables have several key features and requirements to withstand the demanding marine environment:1. Fire resistance: Marine shipboard cables are required to have excellent fire resistance properties to ensure the safety of the vessel and its occupants. They are designed to resist the......

Send Inquiry

Product Description

Marine shipboard cables have several key features and requirements to withstand the demanding marine environment:

1. Fire resistance: Marine shipboard cables are required to have excellent fire resistance properties to ensure the safety of the vessel and its occupants. They are designed to resist the spread of fire and maintain circuit integrity even in extreme heat conditions.

2. Oil and chemical resistance: Marine shipboard cables should be resistant to oil, fuel, and other chemicals commonly found in marine environments. This resistance helps to prevent degradation and maintain the integrity of the cable insulation and jacketing.

3. Water resistance: Marine shipboard cables are designed to be water-resistant or waterproof to withstand exposure to seawater, rain, and high humidity. They have specialized insulation and jacketing materials that protect the conductors from moisture and prevent electrical failures.

4. Mechanical strength: Marine shipboard cables are engineered to have high mechanical strength to withstand the vibrations, impacts, and stresses experienced during ship operations. They are designed to resist abrasion, bending, and pulling forces.

5. Electromagnetic compatibility (EMC): Marine shipboard cables are designed to minimize electromagnetic interference (EMI) and ensure proper signal transmission without interference from other electrical systems on board. This helps to maintain the reliability of communication and control systems.

6. Voltage rating: Marine shipboard cables are available in different voltage ratings to meet the specific power requirements of different ship systems. Common voltage ratings include 300V, 600V, and 1kV.